Royalstar Inspection provides third-party testing and certification services. Four areas in the detection of industrial

Royalstar Inspection provides third-party testing and certification services. Four areas in the detection of industrial

products, consumer products testing, trade protection and life science, the detection of harmful substances, safety testing, EMC, environmental safety testing, the reliability of electrical and electronic products, and failure analysis, materials, reliability and failure analysis of metallic materials analysis of non-metallic materials, textiles, footwear, leather testing, detection of all kinds of toy products, automobile parts detection, food, medicines, cosmetics, animal feed and food packaging and contact materials testing, inspection, audit and cooperation compliance services, measurement and calibration and instrument maintenance, certification and training, the semiconductor and related fields detection, ship management of hazardous substances for transport of goods identification, application software development and testing of a number of comprehensive testing and certification services.

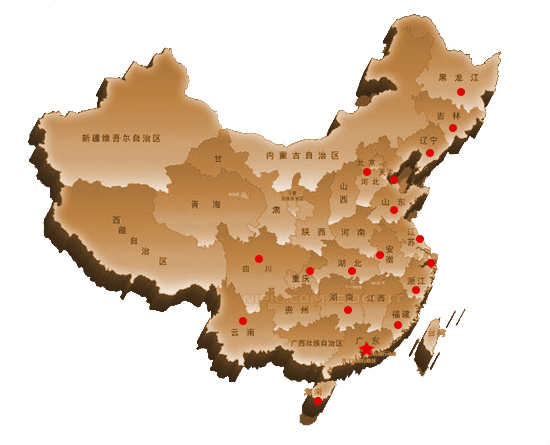

Royalstar Inspection is headquartered in Shenzhen, is currently in Shanghai, Beijing, Suzhou, Hongkong, Taiwan, Shunde, Zhongshan, Tianjin, Guangzhou, Shantou, Jiangmen, Xiamen, Huizhou, Nanjing, Ningbo, Qingdao, Hangzhou, Wuxi, Xian, Hefei, Chengdu, Chongqing, Dalian, Wuhan, Nanchang, Yangzhou, Wenzhou, Changchun, Zhuhai, Kunshan and other places have a professional inspection staff, for customers at home and abroad to provide convenient services.

YOU CARE, WE CARE

Royalstar Inspection With advanced technology and superior service concept, the majority of enterprises to solve a number of quality problems, reducing the risk of clients in international trade, has won the trust of customers and the community.

Quality control

Quality control is important for all the buyers, but it is not so important in any other places as in Asia. When you and your clients are in another side of the world, it results very practical to have someone near to the manufacturer who really understands your concept of quality. With the professional work of our own quality-control team who are specialized in different sectors, Leke Inspection offers solutions that really mark difference.

What inspection services do we offer?

Inspection of the sample

A good quality control begins with correct samples. According to all the quality requirements, we help to correct and confirm the samples in conformity to the clients specifications.

Inspection of raw materials

This Inspection takes place at the beginning of the production, so it allows an early (and thus cost-saving) prevention of defective components as well as timely corrections if needed.

Our Objective is to identify the potential problems as early as possible to avoid the serious consequences as well as save time and cost from the beginning.

Inspection of production

This inspection is carried out various times during the production process to ensure all the contractual obligations regarding product descriptions and other requirements are completed. If any improvement recommendations and rectifications advices have been given during the Initial Production Inspection, the During Production Inspection will enable to check whether these advices have been successfully followed. More generally, this process allows detecting all the possible quality problems and giving recommendations on-site, so that the quality is maintained throughout the entire production phase, and helping monitor if the expected production capacity is reached to complete the order on the time.

Inspection before shipment

The Inspection before Loading is carried out when a minimum of 80% of the goods ordered are produced. The Inspection ensures that the production is in accordance with the specifications, purchase orders or letters of credit. Accordingly, we will inform the clients the situation of their goods for their final, decision.

Inspection of container

Once received the client s decision, this inspection will be carried out. The inspector monitors the entire loading phase counting all the goods loaded into the container and ensure the container is in good condition. Our objective of this inspection is to make sure the right products will be delivered and keep our clients informed in advance of the correct quantity loaded.